Bainite Vs Pearlite

However greater undercooling by rapid quenching results in the formation of martensite or bainite instead of pearlite. It should not be confused with hardness which is a measure of a samples resistance to indentation or scratching.

Materials Science Difference Between Pearlite Bainite And Martensite فرع علم المواد Facebook

Pearlite Martensite Austenite Dan Bainite Alnahyan

Res Mdpi Com

It is an important property for welding since it is inversely proportional to weldability that is the ease of welding a material.

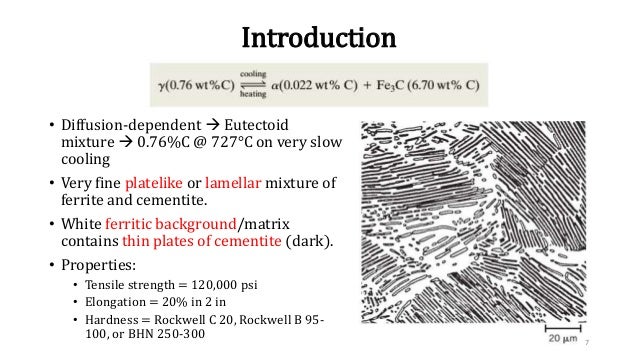

Bainite vs pearlite. The individual particles are much finer than in pearlite. A two-phase micro-constituent containing a fine needle-like microstructure of ferrite and cementite that forms in steels that are isothermally transformed at. It is a hard brittle material normally classified as a ceramic in its pure form and is a frequently found and important constituent in ferrous metallurgy.

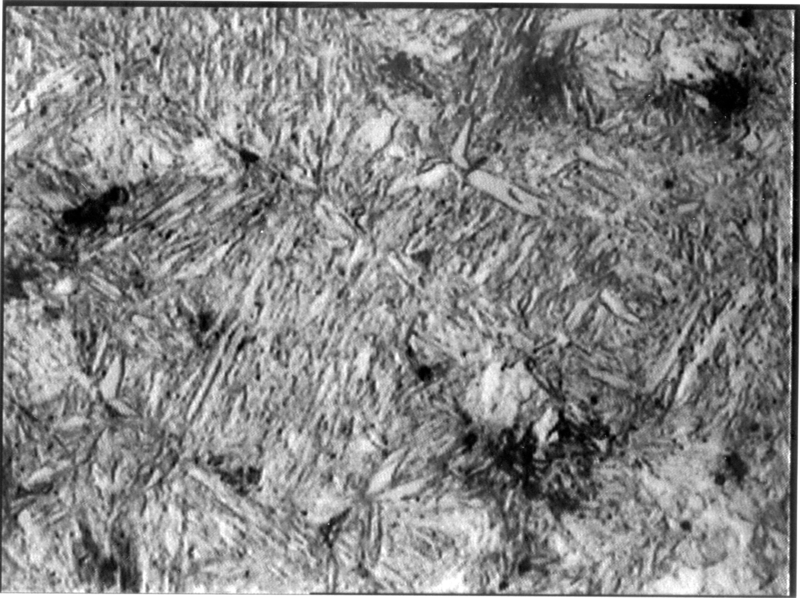

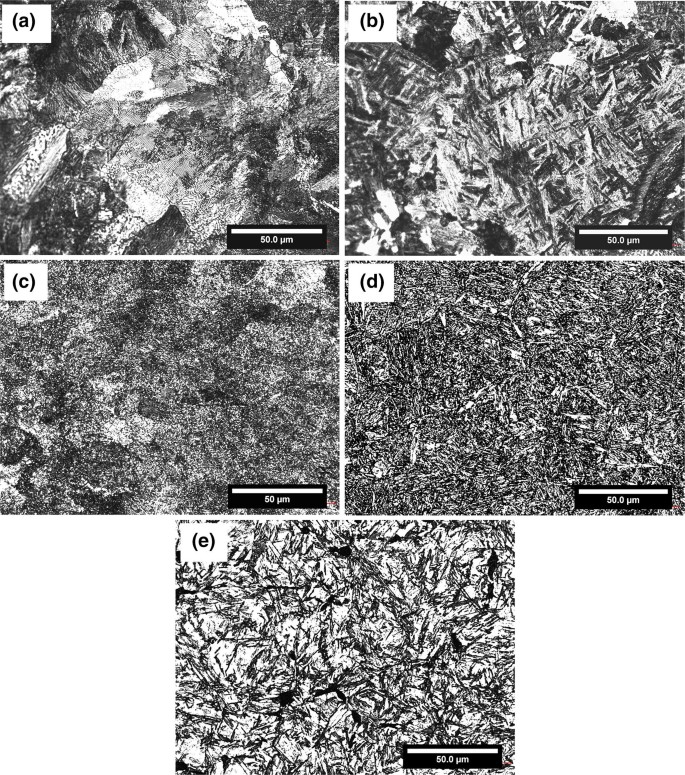

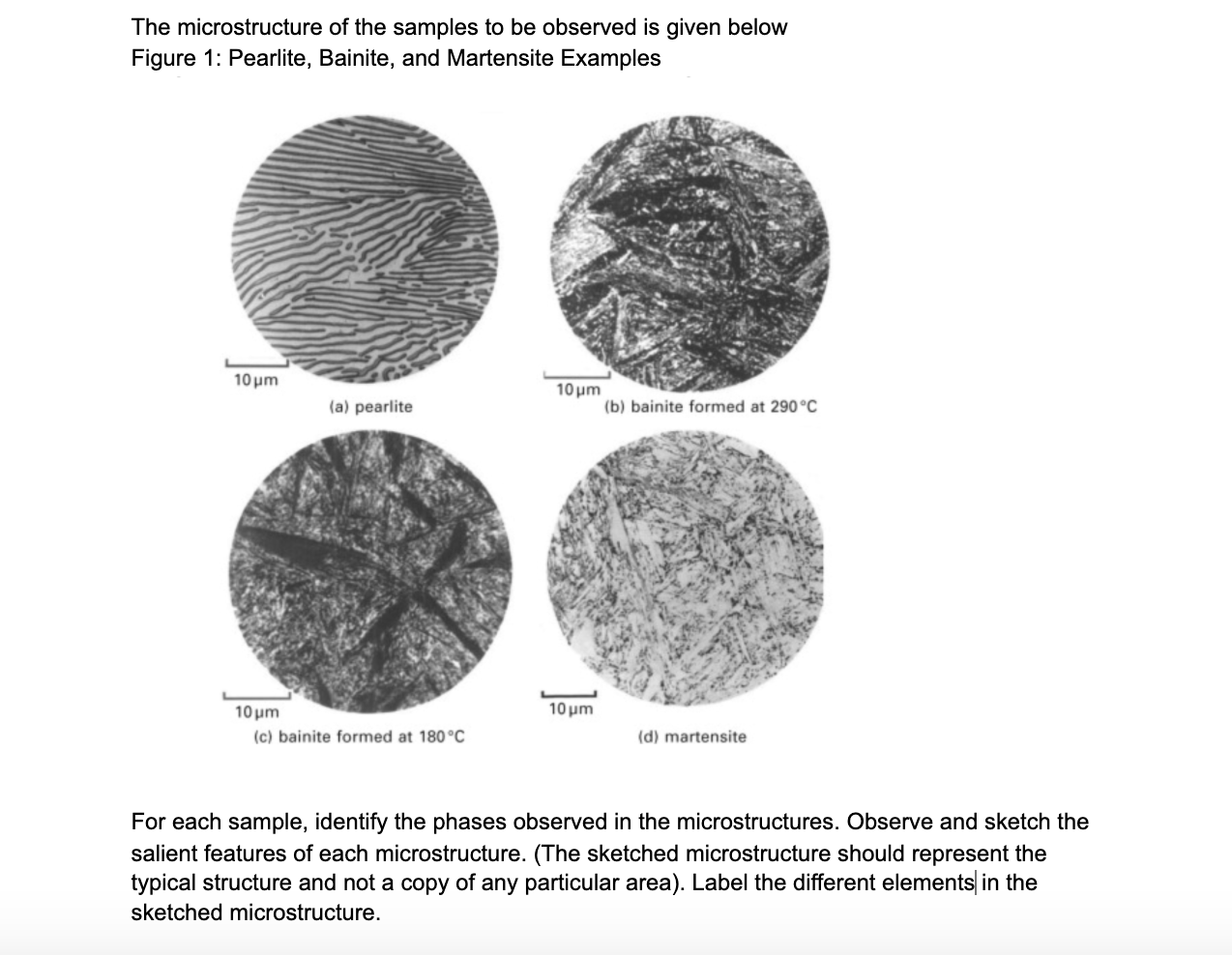

The appearance of bainite may vary between feathery mass of fine cementite and ferrite for bainite formed around 480C and dark acicular needle shaped crystals for bainite formed in the region of around 310C. Bainite consists like pearlite of a ferrite matrix in which particles of cementite are embedded. 357463527-Password-Listpdf - Free ebook download as PDF File pdf Text File txt or read book online for free.

STRUCTURE OF MATERIALS The Key to its Properties. Coarse pearlite is produced when atoms diffuse rapidly after phases that form pearlite nucleate. The layout of nuclear power plants comprises two major parts.

INDIAN INSTITUTE OF TECHNOLOGY KANPUR. Material organization changes different. Conventional HSLA steels are single-phase ferritic steels with a potential for some pearlite in C-Mn steels.

The hardenability of steel is a function of the carbon content of the material other alloying elements and the grain size of the austenite. By weight it is 667 carbon and 933 iron. Cast Iron is being used in a wide area of industry ie.

Appearing as a fine non-lamellar structure bainite commonly consists of ferrite carbide and retained austenite. The resulting hardness is about 28 HRC. Fraction of pearlite de pendent on alloy des ign and processing.

Thus the characteristic pearlite and bainite obtained in medium- and high-carbon steels are not typically observed in low-carbon steels used for magnetic applications. Cementite or iron carbide is a compound of iron and carbon more precisely an intermediate transition metal carbide with the formula Fe 3 C. Has desirable strength-ductility combination harder than pearlite but not as hard as martensite Hardening at Microscopic Scale.

This transformation is complete at the pearlite finish time Pf. The hardenability of a metal alloy is the depth to which a material is hardened after putting it through a heat treatment process. Follow microstructural development in Cast Iron types to learn about graphite nucleation mechanism lediburite formation and eutectic and eutectoid reactions within cast iron.

What Are the Key Features of Martensite. Academiaedu is a platform for academics to share research papers. Microstructures after certain heat treatments.

Amount pearlite amount bainite amount martensite Vickers hardness yield stress ASTM grain size number Youngss modulus plastic strain austenite plastic strain ferrite plastic strain pearlite plastic strain bainite plastic strain martensite temperature rate current temperature reference temperature plastic strain rate MAT_249 version R9. Bainite is a type of steel thats produced by cooling faster than pearlite but slower than martensite. This website was founded as a non-profit project built entirely by a group of young engineers.

The largest difference between full annealing and normalizing is the lamellar spacing of the resulting pearlite. A heat treatment used to produce a soft coarse pearlite in a steel by austenitizing then furnace cooling. A nuclear power plant is a thermal power plant in which a nuclear reactor is used to generate large amounts of heatThis heat is used to generate steam directly or via steam generator which drives a steam turbine connected to a generator which produces electricity.

What is a nuclear power plant. Materials and Metallurgical Engineering. The nuclear island and.

The Material organization After normalizing. In these cases it is similar in constitution to pearlite but. It has an orthorhombic crystal structure.

A third type of steel thats created in the production of modern Japanese swords is bainite which falls somewhere between martensite and pearlite. This choice minimizes the second phase which is important from the standpoint of both induction- and structure-sensitive properties such as permeability and coercive force. Pearlite occurs when full diffusion is achieved.

The sub-aluminum steel is ferrite pearlite the eutectoid steel is pearlite. Very coarse pearlite is very soft. Then martensite or bainite transformation is performed by rapidly cooling to a temperature below the critical cooling rate to below Ms or isothermal near Ms.

Boilers water conduit pipes in Oil and Gas Industry. Minimum yield strength l evels of 70 ksi the micros tructure used is a ferritebainite or ferriteacicular ferrite a low car bon. The entire website is based on our personal perspectives and does not represent any companys view in.

If the steel is quenched too slowly to achieve martensite you will end up with bainite or pearlite. The resulting microstructure is 62 bainite 32 proeutechtoid ferrite and approximately 6 pearlite. Cast Iron is considered the most widely used metal-matrix composite from the 1920s.

Bainite is one of the decomposition products that may form when austenite is cooled past the eutectoid temperature of 727 C. Manufacturing Engineering and Technology 6th Edition Serope Kalpakjian Stephen Schmidpdf. AHSS are primarily steels with a multiphase microstructure containing one or more phases other than ferrite pearlite or cementite for example martensite bainite austenite andor retained austenite in quantities sufficient to produce unique mechanical properties.

Martensite is the end product of conventional quenching on steel. Bainite occurs when the carbon atoms are able to partially diffuse out of the lattice.

Pearlite Bainite And Martensite In Carbon Steel Report

Comparative Corrosion Behavior Of Five Microstructures Pearlite Bainite Spheroidized Martensite And Tempered Martensite Made From A High Carbon Steel Springerlink

Bainitic Structure An Overview Sciencedirect Topics

Solved The Microstructure Of The Samples To Be Observed Is Chegg Com

Ttt Charts

Characteristics Of Pearlite Bainite And Martensite

Bainite Vs Martensite The Secret To Ultimate Toughness Knife Steel Nerds

Initial Microstructures A Ferrite Pearlite B Download Scientific Diagram

0 Response to "Bainite Vs Pearlite"

Post a Comment